Are your floors looking a bit sorry for themselves, worse for wear and in much need of an upgrade? Or maybe you want to completely transform the style and personality of your rooms with a brand-new interior design scheme that will breathe new life into your living space.

Well, if you’re seeking to buy engineered wood flooring, you’re in the right place! If you like the aesthetic of hardwood flooring but it’s a bit out of your budget range, engineered wooden flooring is an excellent choice.

We’re sure you have numerous questions and queries about what to look for when buying engineered hardwood flooring, but that’s where we come in! Here at Tile Superstore, we will put your mind at ease with this handy comprehensive guide, so you’ll be ready to embark on your journey of discovering engineered wood floorboards full of confidence.

Table of contents

- What is engineered wood flooring?

- What are the benefits of engineered wood flooring?

- What are the different types of engineered wood species?

- What are the various types of engineered wood finishes?

- What is the best thickness for engineered wood flooring?

- Laying engineered wood flooring

- How much does engineered wood flooring cost in the UK?

- Final thoughts

What is engineered wood flooring?

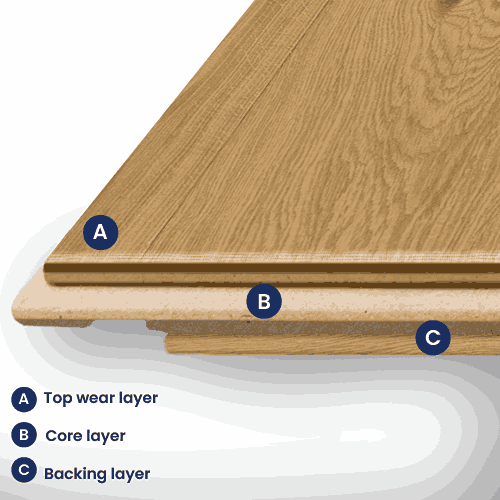

As a popular and versatile type of flooring, engineered wooden flooring combines the natural beauty of hardwood with modern engineering techniques. It is constructed using multiple layers of timber, each with a specific purpose to create a highly stable and durable flooring solution.

Engineered wood flooring typically consists of three main layers, which are bonded together during the manufacturing process using strong adhesives and high-pressure techniques. So, without further ado, let’s peel back those layers to see what’s underneath!

Top wear layer

Made from real hardwood veneer, the wear layer offers the perfect combination of functionality and stunning aesthetics. Typically, its thickness will vary between 2mm and 6mm. It delivers a naturally authentic and luxurious appearance while withstanding foot traffic within your busy home.

Additionally, it comes in various species of hardwood, offering a wide range of colours, grain patterns and finishes to choose from, but don’t worry we’ll cover those details later!

Core layer

Residing beneath the wear layer, the core layer usually comprises several layers of plywood or high-density fibreboard (HDF). These layers are arranged in a cross-grain orientation for exceptional stability and to prevent significant expansion and contraction when exposed to fluctuations in humidity and temperature.

Backing layer

The bottom layer provides additional support for the flooring and acts as a balancing layer. Much like the core layer, it is also made from plywood or HDF.

What are the benefits of engineered wood flooring?

You might be wondering what the benefits of engineered wood vs solid wood flooring are. What’s the point of engineered wood flooring if real solid wood exists? You’ll be pleased to find that it boasts numerous advantages, making it a highly desirable and practical choice for homeowners.

Natural wood appearance

Providing the authentic and elegant appearance of real hardwood, engineered wood flooring features unique grain patterns and rich colours for the same timeless appeal as solid wood without breaking the bank.

Resistance to temperature and moisture

Thanks to the stability and sturdiness of its core, engineered wood flooring is less prone to warping, swelling or shrinking and will endure changes in temperature or humidity. This makes it ideal for installation in areas where solid hardwood may not be recommended, like areas with higher moisture levels or underfloor heating systems.

However, make sure to double-check with the manufacturer for compatibility in bathrooms. While engineered flooring is less sensitive to humidity, it’s not always invincible. The glue used might not be impenetrable, and areas prone to water spillages and humidity will cause the flooring to buckle.

Hard-wearing

Designed to be long-lasting and highly durable, it can endure daily wear and tear, making it an excellent investment for high-traffic areas in your home, especially if you have children or pets.

Low maintenance

With minimal maintenance requirements, engineered wood flooring can stay looking beautiful without the need for extensive upkeep. Unlike solid wood, it is less susceptible to moisture-related issues, making it easier to maintain.

For general day-to-day cleaning, ensure you regularly sweep or vacuum the floor. For a slightly deeper clean, occasionally mopping the area with a damp mop, using manufacturer-recommended cleaning solutions, will ensure your floor remains in pristine condition.

A word to wise, make sure you clean up spillages as soon as possible, otherwise, your floor may delaminate. Try to keep your flooring as dry as possible, avoiding sprays or steam mops.

Environmentally friendly

By using a thin layer of genuine wood on top of a composite core, engineered wood flooring maximises the use of natural resources, reducing the amount of hardwood needed to cover a larger surface area. Additionally, some engineered wood products are manufactured from sustainable and responsibly sourced materials, contributing to an eco-friendlier choice.

Cost-effective

Compared to solid hardwood, engineered wood flooring is often more budget-friendly. While the initial cost may vary based on the quality of the top layer and core materials, overall, engineered wood tends to be more affordable, making that luxurious finish you’ve long dreamed of much more achievable than you perhaps first imagined.

What are the different types of engineered wood species?

With an array of species available, engineered wood flooring offers a diverse selection to complement any interior design preference. There’s sure to be an option to suit your taste, adding a unique character and charm to your living space.

Oak

As one of the most common and versatile wood species utilised, engineered oak flooring features a prominent grain pattern and comes in various shades, from light to dark. Known for its durability and timeless appeal, it is a popular choice for traditional and contemporary interiors alike. Creating a cosy and inviting atmosphere, you can pair it with rustic furniture for a charming country cottage look or combine it with sleek, modern décor for a stylish contrast.

Maple

With a smooth and even grain, engineered maple flooring showcases a light colour, ranging from creamy white to pale brown. Its uniform appearance and natural brightness lend a fresh, modern aesthetic to suit any room. Perfect for contemporary interiors or Scandinavian-inspired designs that embrace minimalism and natural light, it will enhance the brightness of your space.

Ash

As another neutral and pale-coloured flooring with light brown to soft white tones, ash engineered wood often has bold grain patterns that add character and visual appeal to the flooring. Ideal for minimalist or coastal-themed interiors, it will emphasise a light and airy feel, accentuating a sense of space and brightness.

Beech

With warm, inviting hues ranging from pale cream to reddish-brown, beech engineered wood offers versatility. Its smooth texture and subtle grain patterns complement any interior style. Pairing with both modern and classic décor alike, it will help you achieve an enduring and understated elegance in your home.

Acacia

Displaying a range of colours from golden brown to deep chocolate hues, acacia flooring boasts distinctive grain variations, which add a touch of rustic charm and warmth to any room, from farmhouse-style interiors to a cosy cottage retreat.

Walnut

Walnut engineered wood is valued for its rich, dark brown colouring and striking grain patterns. It exudes an air of luxury and style, making it an excellent choice for upscale and refined spaces. Thanks to its high density and durability, it is a superb option for high-heat environments. Adding a touch of sophistication to your home, it pairs well with rich, opulent furnishings for an elegant ambience.

What are the various types of engineered wood finishes?

With a wide variety of finishes to choose from, each type contributes to the overall appearance and protection of the engineered wood flooring, allowing you to achieve your desired ambience and interior design vision.

Unfinished

Unfinished engineered wood flooring does what it says on the tin without any surface treatment or finish applied. So, you can customise the appearance of the wood yourself by applying your preferred finish, stain or sealant after installation. It gives you the freedom to create a truly unique look tailored to your individual design preferences and the flexibility to match existing colour schemes.

Smooth

A smooth finish provides a sleek and clean appearance, with the fully visible natural beauty and grain patterns of the wood. This finish is ideal for contemporary and modern interiors.

Glossy

Delivering a shiny and reflective surface, a glossy finish creates a polished look. It can add depth and dimension to the flooring but may show scratches and imperfections more visibly.

Matt

Offering a low-sheen appearance, a matt finish provides a more natural and understated look to the flooring and is similar in appearance to oil. It is less reflective than glossy finishes and more likely to conceal dust and blemishes, making it a popular choice for a modern ambience and busy family homes.

Satin

A satin finish strikes the perfect balance between glossy and matt, providing a subtle sheen that enhances the natural beauty of the wood without being overly reflective. It adds a touch of sophistication, making it a versatile choice for various interior styles.

Lacquered

Lacquered finishes involve applying a layer of lacquer to seal the wood, creating a durable, hard-wearing surface. They provide excellent protection against scratches, spills and stains, making them ideal for frequently used rooms, such as hallways. What’s more, a lacquered finish performs well against moisture, shielding your wood from the damaging effects of water and making it perfect for areas prone to spillages, such as your kitchen.

Oiled

Oiled engineered wood flooring is treated with natural oils that penetrate the wood fibres, enhancing its beauty and protecting it from within. This finish brings out the natural lustre and aesthetic of the wood, creating a warm atmosphere. That said, it does require periodic re-oiling for maintenance, which helps keep the wood nourished and looking vibrant over time.

For further protection, we recommend adding an extra layer of oil once your flooring is installed. Bear in mind though, oil doesn’t offer the same protection as lacquer, therefore, is less suited to high-traffic areas.

Brushed

For a brushed finish, the surface of the wood is lightly brushed to remove the softer grain, leaving the harder grain more prominent. This results in a textured appearance that hides minor scratches and scuffs. With only the strongest grains remaining on the surface, the flooring will be tougher and more robust. Additionally, you can combine the brushed effect with either a lacquered finish or an oiled finish, giving you the best of both worlds.

Hand scraped

Simulating the appearance of traditional craftsmanship, the wood is manually scraped to create subtle grooves and indentations. This adds texture to the flooring for an aged and weathered aesthetic.

White-washed

White-washed finishes involve applying a light, opaque stain to the wood, giving it a soft and airy appearance, often associated with coastal and beach-inspired interiors.

Smoked

The smoked finish is achieved through an age-old process that involves exposing the wood to ammonia fumes for approximately twenty days. This treatment shrinks the wood so that it is denser and more resilient. In addition, it darkens the colour of the wood, creating rich, deep tones while preserving its natural grain patterns, giving the engineered wood flooring a distinct appearance.

What is the best thickness for engineered wood flooring?

Generally, engineered wood flooring comes in a thickness ranging from 9.5mm up to 20mm. The best thickness depends on various factors, including your subfloor type, the level of foot traffic and your personal preferences.

The thicker your engineered wood flooring is, the more stable and resistant to warping it will be. If you’re installing it in areas with fluctuating humidity levels, such as areas prone to moisture, a thicker plank, like 18mm or 20mm, is recommended for enhanced durability. What’s more, thick flooring is great for absorbing sound and minimising noise levels. It also has the potential to be re-sanded more, so it’ll last longer.

Thin engineered wood flooring, such as 14mm or 15mm, may be more appropriate for installations over existing flooring, where height clearance is a concern, while 11mm is suited to spaces with low foot traffic. In addition, if you want to install underfloor heating, thinner planks will be more efficient at transferring heat.

Nevertheless, your budget will also play a part in the thickness of your engineered wood flooring. The thicker the veneer, the more material used and the higher the costs. Although thicker flooring will last longer, you’ll have to decide for yourself what you feel you can afford.

Laying engineered wood flooring

Once you’ve invested in your flooring, you’ll be ready (and excited!) to get started. How to lay your engineered wood flooring will depend on your chosen installation method and the type of planks you have purchased, either click-together or tongue-and-groove edges. If done correctly, laying engineered timber floors can be a rewarding DIY project.

Before you begin, allow your engineered wood flooring to acclimate to the room’s conditions. Place the unopened boxes of flooring in the room for at least 72 hours, ensuring the temperature and humidity levels are consistent. For optimal results, it’s best to let your flooring acclimatise for 7 days. The longer the acclimatisation period, the better.

Prepare your subfloor, making sure it is clean, level and dry. If necessary, use a levelling compound for uneven areas and a damp-proof membrane for concrete subfloors. Remember to choose an appropriate underlayment – this will depend on the type of installation, whether it’s floating, glue-down or nail-down.

During installation, leave an expansion gap around the perimeter of the room to accommodate wood movement, following the manufacturer’s guidelines. Stagger the end joints of the planks to create a visually pleasing and stable layout. Randomised joins will ensure your flooring looks natural.

How much does engineered wood flooring cost in the UK?

You’re probably wondering; how much does engineered wooden flooring cost in the UK? This can vary based on several factors, including the brand, quality, wood species, finish and thickness of the planks. On top of that, don’t forget to think about installation costs and any additional services, such as underlayment and accessories.

Engineered wood flooring on its own can cost anywhere in the range of £30 per square metre to £165 per square metre and upwards. High-quality, premium options will be at the higher end of the price range, while more budget-friendly options will be at the lower end. Or, as the old saying goes, “You get what you pay for”, with thicker and higher quality flooring lasting and looking good for longer than cheaper and thinner materials.

Final thoughts

Engineered wood flooring is an excellent choice for those seeking an affordable alternative to hardwood flooring without compromising on aesthetics. Its multi-layered construction ensures stability and durability while providing the natural beauty of real wood. With proper installation and maintenance, engineered wood flooring can be a long-lasting investment.

Here at Tile Superstore, we offer a wide range of engineered wood flooring styles, finishes and colours at varying prices to suit your budget and installation needs. So, what are you waiting for? You can find the perfect fit for your living space and transform your home today!